Sidebar

Acoustical server cabinet with thermal management up to 7 kW

Self-contained air-conditioned server cabinet for IT loads up to 4 kW

Closed loop 25 kW water-cooled module cools one or two cabinets

Point of use cooling to remove 20kW of heat load within a row of data center racks.

Modular locking solutions for data cabinets

REGY allow you to start with a basic package to enable monitoring and access control over a single site. Expand to 100,000 cabinets, one at a time. Each computer cabinet can be monitored using REGY Pro Server.

REGY Pro Server automatically recognizes locks, cameras, sensors, and access control hardware. It’s instantly compatible with thousands of third party IP cameras. The REGY Pro server allows you to send a range of notifications based on lock or sensor events, including recorded video events sent via email or an MMS.

Monitor existing equipment or add additional sensors

It’s easy to integrate with existing solutions using SNMP, MODBUS & Virtual Sensors or add additional…

REGY makes it easy to add a wide range of sensors and automate corrective action, apply software updates and distribute notifications to all of your remote sites.

Create schedules that power off lights and equipment in unoccupied sites, enable or disable an engineer’s access, reboot unresponsive equipment and even unlock sites remotely.

- REGY Base Units

- High Resolution Digital Cameras,

- Environmental Sensors,

- Siren Strobe Alarms,

- Electronic Locks

- Temperature and Humidity Sensors

- REGY Access Control

- Smoke Detectors,

- Power Meters,

- Relay Switches,

- Proximity Readers

- and more…

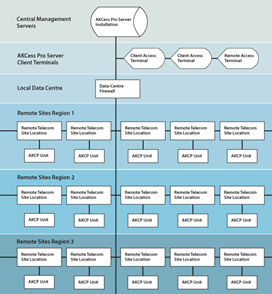

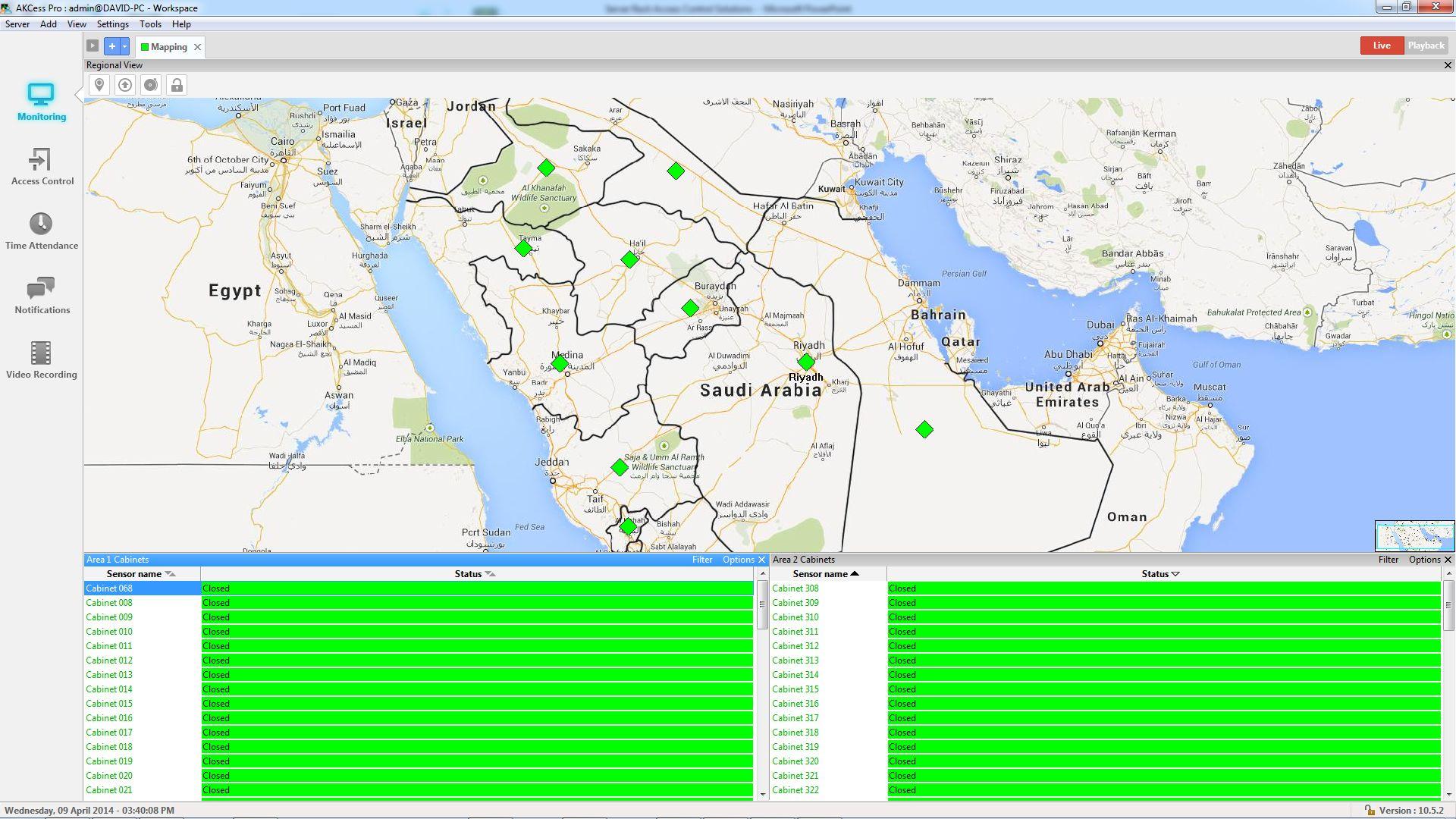

The REGY Pro Server monitors all of your remote sites over any number of regions or locations.

For cabinets located in remote locations REGY design and manufacture complete, off-grid system solutions that allow you to monitor remote sites using a cellular network.

REGY’s on-board SIM-Modem ensures that your system is able to send and receive :

- New User / Card Data

- Cabinet or Door Permissions,

- Remote Unlock Actions,

- Remote Access Logs,

- Sensor Data Logging,

- Alerts and Notifications,

- Remote Site CCTV video capture and more…

Access database and logs stored remotely on each control unit.

REGY’s access control hardware does not need a connection to the central server to authenticate user access to each site after having been configured.

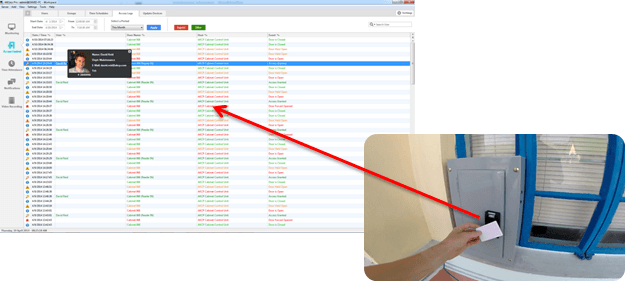

REGY’s Access Control system can also administer remote site engineer access. Card numbers can be collected and sent back to the central server for administration in real time.

No data is lost during network outages

If the data link between the central server and the remote site hardware is interrupted. The remote site hardware will collect and store all access, sensor and video information locally and send it once communication to the central server has been restored.

Access authorisation on a time of day, and day of week basis is stored for each employee and for each cabinet

Access Permissions can be added, amended or revoked at any time.

Updates to Access Permissions are distributed to all cabinets locations from the server. No additional maintenance teams are required.

Remote BTS Site Access Control Package

Features :

- RFID Weigand Input

- Lock Output

- External Lock Override Input

- Onboard 3G Modem with Antenna

- Ultra-Low Power Consumption

Includes:

- SP2+

- RFID Weigand reader

- Fail Secure Bolt with Mechanical Override

- Rechargeable power supply and battery monitoring

- REGY Pro Server Door Control License

REGY understand the challenges related to distributed network installations. REGY designs and manufactures complete, off-grid system solutions that allow you to monitor remote sites, even over a cellular network.

REGY’s on-board SIM-Modem ensures that your system is able to send and receive :

- New User / Card Data

- Cabinet or Door Permissions,

- Remote Unlock Actions,

- Remote Access Logs,

- Sensor Data Logging,

- Alerts and Notifications,

- Remote Site CCTV Video Capture and more…

Buffer events and send when network connectivity has been restored

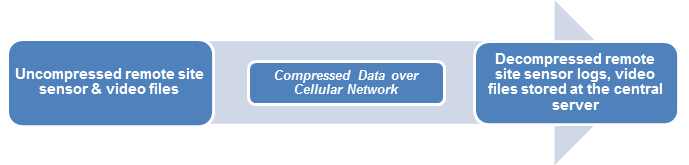

Our intelligent remote site hardware allows you to schedule, not only when this information is sent but what information is transferred to the central office. This helps to lower cellular network costs by decreasing bandwidth requirements and increases the overall system efficiency.

If the data link between the central server and the remote site hardware is interrupted. The remote site hardware will collect and store all access, sensor and video information locally and send it once communication to the central server has been restored.

REGY access control operates autonomously with no need for communication to a central server. To authenticate user access, the remote controller contains a complete database of up to 20,000 users.

Send compressed data only when needed to lower operation costs

Each communication packet sent between the AKCess Pro Server central management software and the remote REGY controller is compressed to save cellular network bandwidth transfer.

Off-grid rechargable power supply and battery monitoring

REGY remote units can be used off-grid with a solar panel and battery charge controller. When in ultra low power mode, REGY remote units draw a very limited amount of power from the battery. This not only extends the life of the battery due to lowering heat dissipation, but also limits the amount of time taken to recharge the battery. This comes in useful in days of limited sunlight hours.

Temperature and Battery Health monitoring sensors can be added to check battery health so that scheduled maintenance can be arranged before power outages occur.

Add Environment Monitoring Sensors

Wireless communications infrastructure and remote telecom tower sites contain a range of equipment that needs to be monitored and protected against theft and damage. REGY manufactures a complete range hardware and software monitoring products for equipment found at remote sites.

REGY’s range of intelligent sensor hardware can monitor a variety of parameters in telecom tower sites. Parameters such as :

|

|

Certain environmental and third party equipment conditions can be detrimental to site efficiency and must be monitored 24/7. Alerts should also be generated when sensors go outside of pre-defined limits.

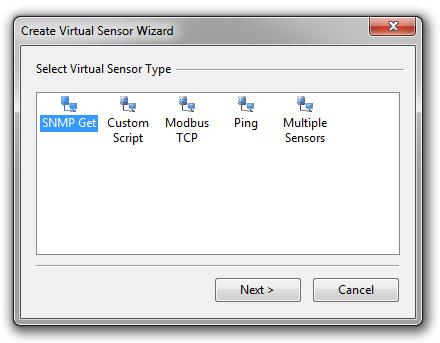

REGY’s Virtual Sensors collect data from third party equipment and can also use the information to send out alerts. Virtual Sensors can be configured to poll data via :

- SNMP Get / SNMP Receiver

- MODBUS

- Custom BASH / PERL Scripting

- PING

Outdoor Cellular Communications Package

Features :

- RFID Weigand Input

- Lock Output

- External Lock Override Input

- Onboard 3G Modem with Antenna

- Ultra-Low Power Consumption

Includes:

- SP2+

- RFID Weigand Reader

- Fail Secure Bolt with mechanical override

- Rechargeable power supply and battery monitoring

- REGY Pro Server Outdoor Cabinet License

Protect against water and smoke damage

REGY environmental monitoring allows for intelligent sensor to be connected to REGY base units such as the securityProbe or sensorProbe series. Sensors are automatically recognized using REGY’s AutoSense feature. REGY lets you monitor and control :

- Temperature

- Humidity

- Smoke

- Water leakage

- Air Flow

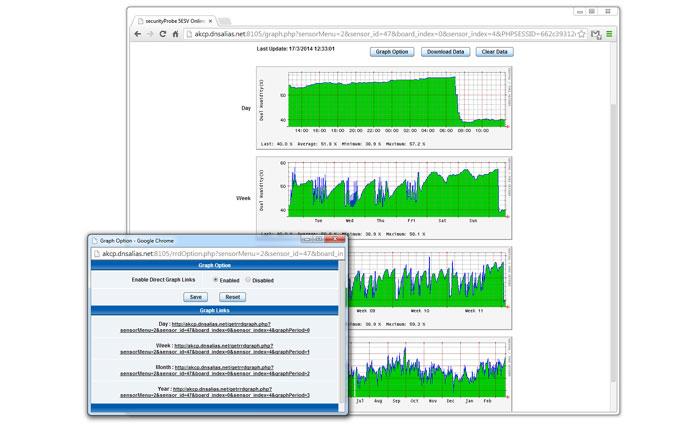

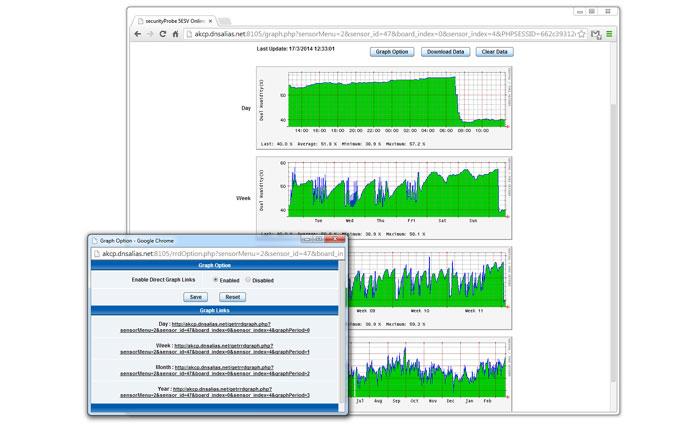

The REGY base units work standalone or can be used with AKCess Pro Server. All sensors include an integrated data collection and graphing package; especially useful in trend and information analysis.

For example, spotWater Sensors can be used to detect water leaks from CRAC systems. Smoke Detectors can be used to detect the initial signs of component fires in data cabinets.

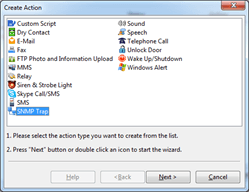

Events that lead to disaster can be used to proactively alert data center staff to maintain equipment correctly or to take corrective action. When events occur, the REGY base unit or AKCess Pro Server can be configured to send :

- SNMP Traps

- Email Messages

- SMS

- Telephone Calls

- Audio Alerts

- Relay On/Off Signals and more…

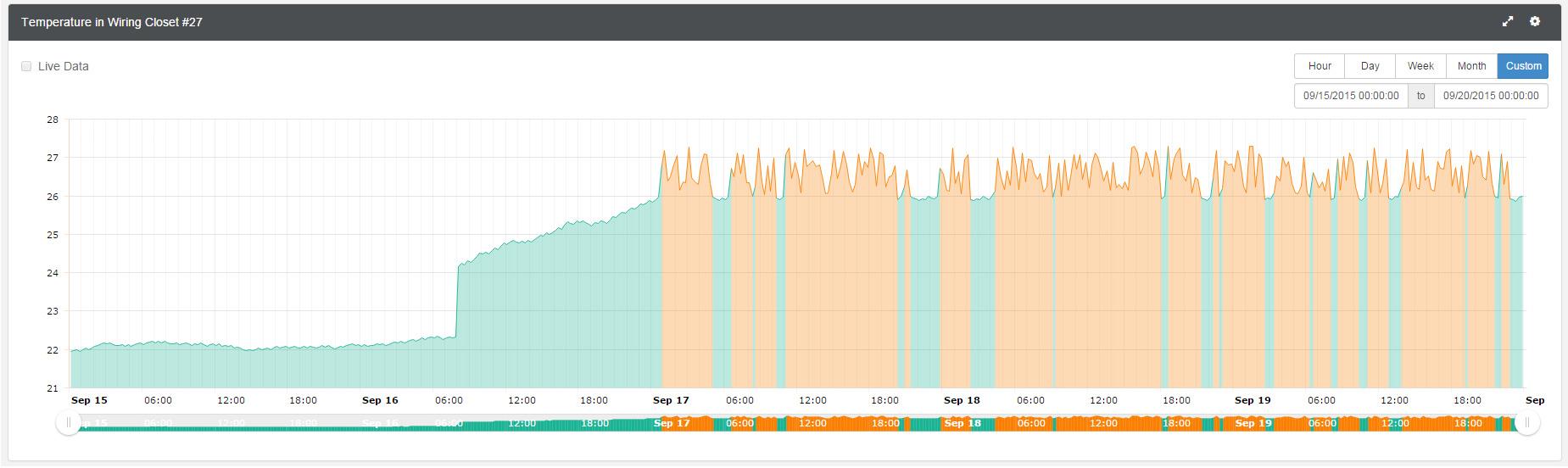

Monitor air flow, temperature and humidity

An essential part of any computer room monitoring system is accurate temperature and humidity monitoring and knowing when CRAC units are on or offline. Rising temperatures lead to system failure, unwanted downtime and costly repairs.

REGY’s equipment helps to avoid these costly errors with easy to configure, cost effective systems that are ready to run, right out of the box.

Graphing of sensor data

Up to 12 REGY Sensors can be graphed on an REGY base unit. The AKCess Pro Server allows for an unlimited number of graphs to be monitored.

Customizable Virtual Sensors

REGY’s Virtual Sensors collect data from third party equipment and can also use the information to send out alerts. Virtual Sensors can be configured to poll data via :

- SNMP Get / SNMP Receiver

- MODBUS

- Custom BASH / PERL Scripting

Cabinet Environmental Monitoring

Features :

- Monitors Temperature, Humidity and Airflow

- Sends SNMPTraps and Email Alerts when thresholds are exceeded

Includes:

- sensorProbe2

- Temperature and Humidity Sensor

- Air Flow Sensor

- REGY Pro Server SP2 License

Data Room Security Monitoring

Features :

- Detect motion in sensitive IT rooms

- Send SNMP Traps and Email Alerts

- Detect if racks are open or closed

- Prevent disaster with Smoke Detectors

Includes:

- sensorProbe8

- Siren Strobe Alarm

- Motion Detection

- Security Sensors

- Smoke Detectors

- REGY Pro Server sensorProbe8 License

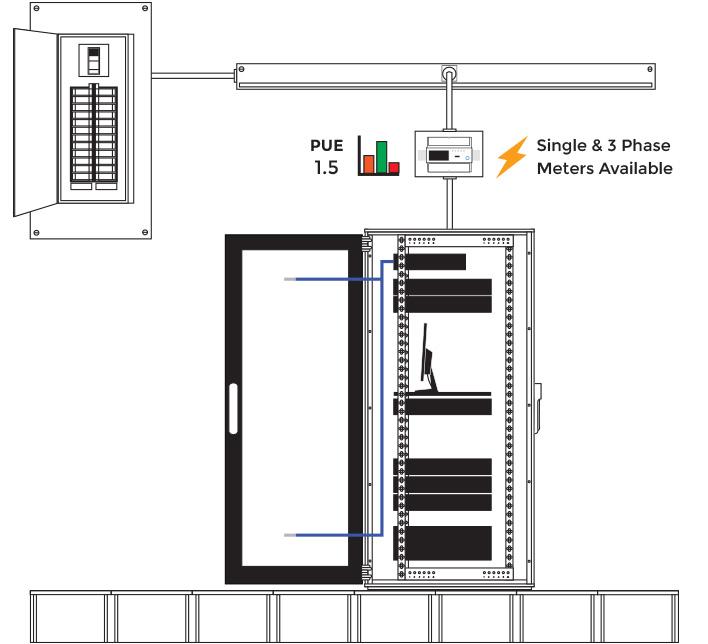

Lower monthly IT energy bills with REGY Power Monitoring Sensors.

Monitor Phase Line Voltages, Current, Power Factor, Active Energy and Active Power

Monitor energy usage in server cabinets.

REGY automatically calculates the efficiency of server room cabinets. Using efficiency data, you can make calculated changes to the way your server room works. Optimize your infrastructure and save money in the process.

30% of servers are under utilized costing approximately $4000 USD per year in excess cooling and electrical costs.

*Study by Uptime Institute

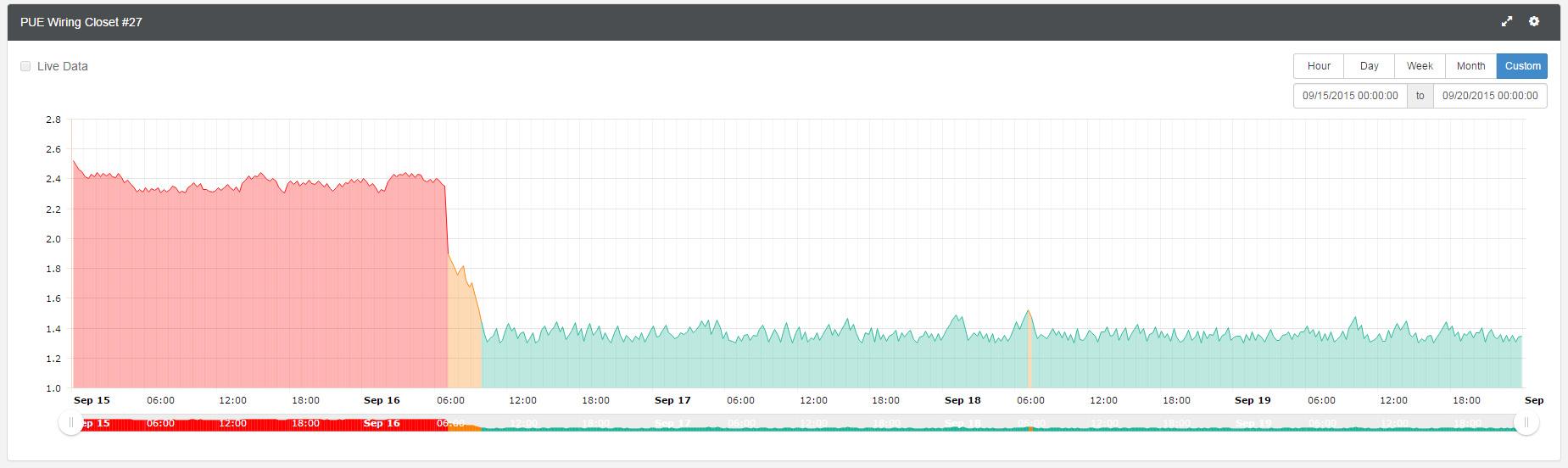

Benchmark and monitor PUE in real time.

Measuring the power consumed by IT and non-IT power enables operators to benchmark and compare power consumption from a single or distributed deployment through Power Usage Effectiveness or PUE calculations.

Evaluate future cost-saving measures using the initial PUE benchmark. PUE and other server room metrics can be tracked over time to help identify server room issues and opportunities for cost savings.

Automatic PUE calculations.

REGY calculate PUE values using data polled from numerous devices. A real time PUE value can be displayed rack by rack or for an entire server room.

Did you know?

Many SMEs use distributed server room deployments instead of a single server room. Smaller wire closet rooms are less energy efficient with typical PUE values of…

2.5

*Study by Berkeley Lab, Improving Energy Efficiency for

Server Rooms and Closets.

PUE cost savings : Server Room vs Wire Closet

In the study "Improving Energy Efficiency for Server Rooms and Closets" from Berkeley Lab they explain how an IT administrator for a medium sized company has ~10 servers, each consuming 500W. A cost comparison can be drawn between a using a wire closet setup and server room configuration using PUE calculations.

|

Typical PUE Value |

Server Room Power Consumption (kW) |

Total Power Consumption of IT and Infrastructure (kW) |

Estimated Monthly Costs ($/Month) |

Monthly Savings if consolidated to a server room |

|

|

Server Room |

2 |

5 |

10 |

876 |

— |

|

Wire Closet |

2.5 |

5 |

12.5 |

1095 |

219 |

This example assumes the cost of electricity is $0.12 per kilowatt-hour (kWh).

While the servers are using the same amount of energy, the costs associated with powering the room varies based on the PUE efficiency of the cooling and power infrastructure. By consolidating server racks to a central server room location you can better control cooling help to save on operating costs from day one.

Monitoring the power consumed by IT and non-IT infrastructure is a crucial element of an IT deployment.

Monitor Power using REGY Virtual Sensors.

Use REGY Virtual Sensors to integrate and monitor IT power from any MODBUS or SNMP enabled device such as a UPS, CRAC or PDU.

Virtual Sensors can be monitored locally on an REGY Platform or the REGY Pro Server DCIM.

Create SNMP Get, Custom Scripts, MODBUS TCP, PING and Multiple (Boolean) Virtual Sensors.

Use REGY Graphing to monitor PUE fluctuations over time.

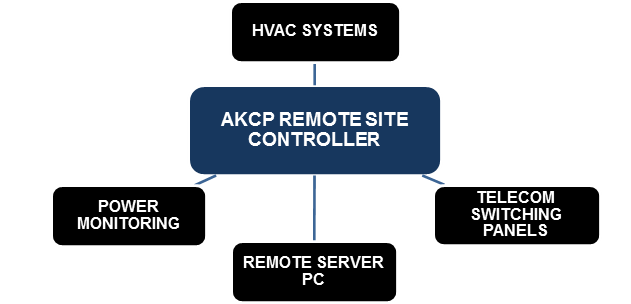

AKCP’s family of sensor and control systems developed over the last 30 years are widely used in industrial applications. Anywhere you need to monitor sensors and control systems our network enabled devices are the first choice.

The sensorProbe+ series is a cost effective and robust solution that can act as a Modbus RTU <-> TCP/IP as well as Modbus RTU or TCP/IP <-> SNMP gateway. It can function as either Master or Slave through the addition of the optional Modbus EXP port on all SP2+ and SPX+ units.

Modbus Gateway is available on both the SPX+ and the SP2+ base units.

sensorProbeX+ (SPX+) comes in a variety of standard configurations to suit your monitoring needs. Additional modules can be added or a complete custom unit can be built so you get only the features you want. Add a Modbus EXP port to monitor third party Modbus devices.

sensorProbe2+ (SP2+) is a compact device, with 4 sensor ports and Modbus TCP/IP support. Upgrade to the SP2+X and change 1 sensor port to an Expansion port which supports Modbus RTU.

Specifications

| General Specifications | |

| Modbus RTU | Modbus RTU connects through the Expansion port (EXP) as a 2-wire connection. |

| Speed | 9600, 19200, 38400, 57600 and 115200 |

| Parity | None, Even, Odd |

| Stop Bit | 1, 2 |

| Databit | 8 |

| Modbus TCP/IP | |

| Host | IP Address |

| Port | 502, 1024-65535 |

| Modbus Slave | |

| Support Modbus Slave RTU and TCP/IP | |

| Can poll up to 32 values with Virtual sensors and up to 3 PMS. | |

| Functions | 0x01 - Read Coil Status |

| 0x02 - Read Input Status | |

| 0x03 - Read Holding Registers | |

| 0x04 - Read Input Registers | |

| Data Type | 16 bits unsigned int |

| 16 bits signed int | |

| 32 bits unsigned int | |

| 32 bits signed int | |

| 32 bits IEEE floating point | |

| Data ordering | low byte first, low word first |

| low byte first, high word first | |

| high byte first, high word first | |

| high byte first, low word first | |

| AKCP's Power Meter Sensor (PMS) |

The SPX+ and SP2+ include a specific interface to online up to three AKCP's Power Meters via Modbus RTU |

| 3rd Party Power Meters support is also possible but requires the purchase of a licences. | |

| Modbus Notifications | The SPX+ and SP2+ support Modbus Write commands via the Notification feature * |

| Functions | 0x05 - Write Single Coil |

| 0x06 - Write Single Register | |

| 0x0F - Write Multiple Coils (32 bits maximum) | |

| 0x10 - write Multiple Registers (2 registers maximum) | |

| * Feature available soon | |

| Modbus Master | |

| Support Modbus Master RTU and TCP/IP | |

| Functions | 0x03 - Read Holding Registers : 32 bits IEEE floating point value |

| 0x04 - Read Input Registers : 32 bits signed int value | |

| Register Address List | All sensors monitored by the SPX+ or SP2+ have a Modbus register automatically assigned, and the user can edit the Modbus register assigned to the sensors. |

| The register list can be consulted on the unit's WebUI page, in System >> Modbus |

smartRack

Add smartRack bundles to your base unit configuration

Current Monitoring

More...

Environmental Monitoring for Site Shelters

Wireless communications infrastructure and remote telecom tower sites contain a range of equipment that needs to be monitored and protected against theft and damage. AKCP manufactures a complete range hardware and software monitoring products for equipment found at remote sites.

- Temperature

- Humidity

- Smoke

- Water leakage

- Air Flow

- Security Sensors

- Motion Detectors

- Detection of AC Power Line Voltage

- Measurement of Digital Voltmeter

- Control Relays and more…

Certain environmental and third party equipment conditions can be detrimental to site efficiency and must be monitored 24/7. Alerts should also be generated when sensors go outside of pre-defined limits.

AKCP’s Virtual Sensors collect data from third party equipment and can also use the information to send out alerts. Virtual Sensors can be configured to poll data via :

- SNMP Get / SNMP Receiver

- MODBUS

- Custom BASH / PERL Scripting

- PING

Front & Back Cabinet Locking Package

Features :

- Records and transfers video to the central server automatically

- Captures employee access attempts

- Monitors cabinet environmental parameters

Includes:

- Cabinet Control Unit 2

- Temperature and Humidity Sensor

- High Definition Digital Camera

- Electronic Swing handle Lock

- AKCess Pro Server Cabinet License

Control Power Remotely

AKCP Sensor Controlled Relays allow you to save time, eliminate site visits and save money. Many equipment problems can be resolved with a simple reboot.

AKCP’s software and hardware relays are perfect for remotely rebooting servers, kiosks, ATMs, digital signage, workstations, servers and any other machines on a distributed network.

Monitor devices using PING or more sophisitcated command response scripts sent from the central server. If the remote equipment responds incorrectly, an encrypted , password protected software shutdown command can be issued. If the system fails to response automatically power cycle equipment that has locked up. Create scheduled reboot actions to refresh devices.

Remote IO Control

AKCP provides low cost dry contacts that can be configured as inputs or outputs. They can detect many inputs such as UPS statuses, security systems, alarm panels or air conditioning statuses.

From sounding audible siren alarms, manual switch on and off relays or even control a cooling system. AKCP give you the flexibility to monitor and respond to physical alert conditions from any location.

Synchronize Video with Event Data

Cabinet and Door Access videos can be reviewed using AKCess Pro Server from the central location. Review hundreds of hours of cabinet access attempts and filter to find critical status video in seconds.

Cameras can be embedded into remote site cabinets to capture entry attempts on cabinets or in telecom rooms.

Choose to record 24/7 or on a sensor event to limit overall bandwidth usage.

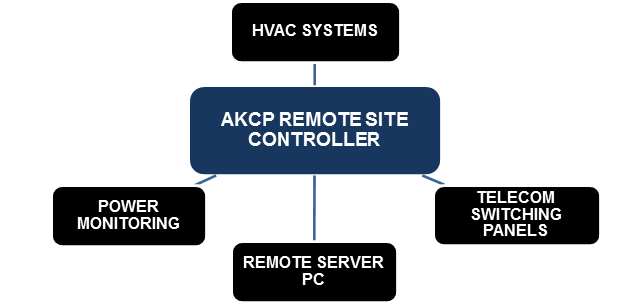

The backbone of AKCP’s BTS Site Access Control monitoring system is the AKCess Pro Server. Installed at a central location, the AKCess Pro Server enables administration and control over your entire BTS Site Access Control infrastructure.

AKCP’s on-board SIM-Modem ensures that your system is able to send and receive :

- New User / Card Data

- Cabinet or Door Permissions,

- Remote Unlock Actions,

- Remote Access Logs,

- Sensor Data Logging,

- Alerts and Notifications,

- Remote Site CCTV Video Capture and more…

Our intelligent remote site hardware allows you to schedule, not only when this information is sent but what information is transferred to the central office. This helps to lower cellular network costs by decreasing bandwidth requirements and increases the overall system efficiency.

If the data link between the central server and the remote site hardware is interrupted. The remote site hardware will collect and store all access, sensor and video information locally and send it once communication to the central server has been restored.

AKCP access control operates autonomously with no need for communication to a central server. To authenticate user access, the remote controller contains a complete database of up to 20,000 users.

Remote BTS Site Access Control Package

Features :

- RFID Weigand Input

- Lock Output

- External Lock Override Input

- Onboard 3G Modem with Antenna

- Ultra-Low Power Consumption

Includes:

- SP2+

- RFID Weigand reader

- Fail Secure Bolt with Mechanical Override

- Rechargeable power supply and battery monitoring

- AKCess Pro Server Door Control License

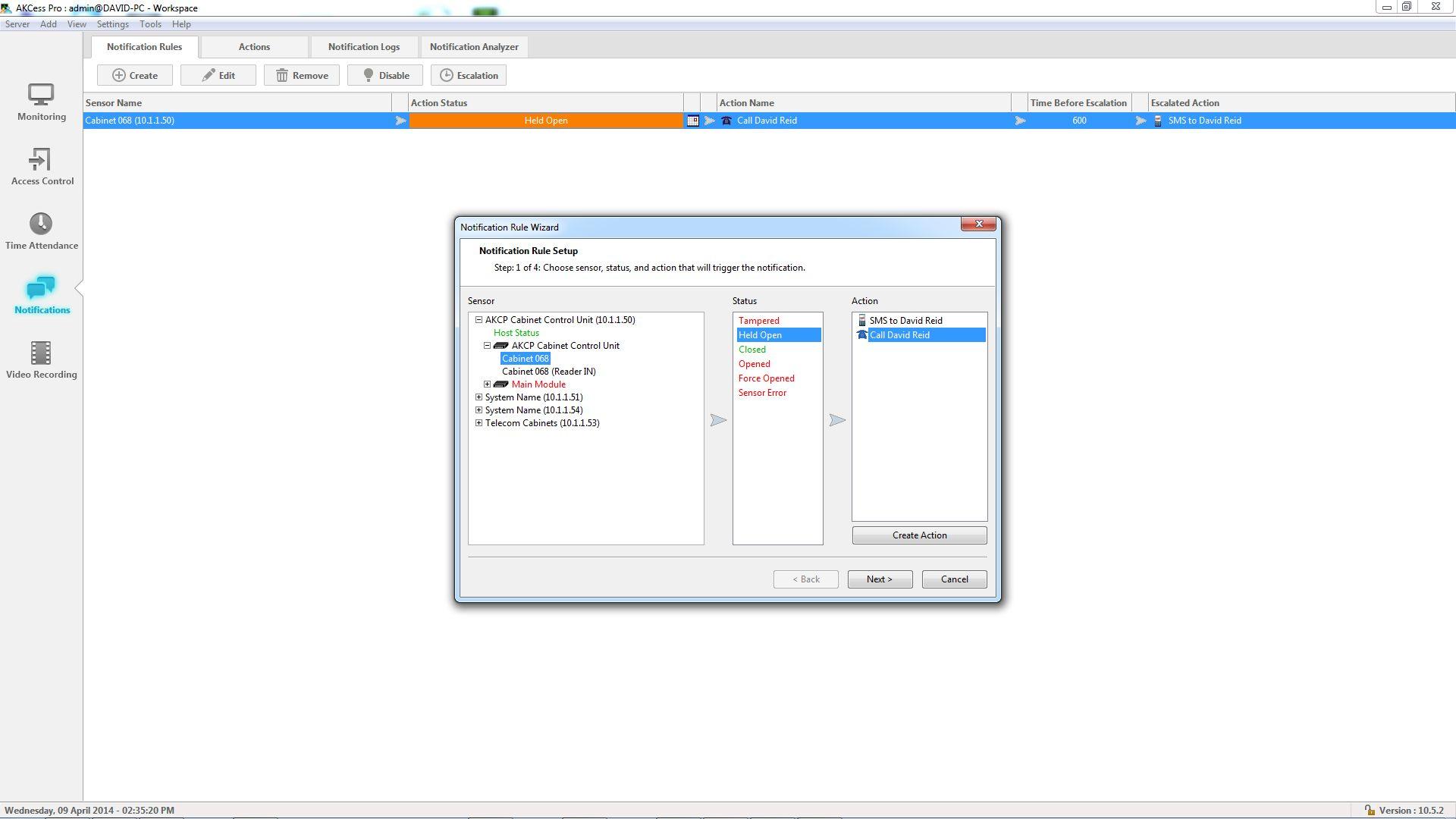

Manage thousands of employees.

AKCess Pro Server makes it easy to add and manage users, groups, door or remote cabinet access schedules from any location.

- Take control of one, easy-to-use interface and manage thousands of sites from any location in the world.

- Names, departments and profile pictures are stored at each central server location.

- Access Permissions can be added amended or revoked at any time.

- Updates to Access Permissions are distributed to all cabinet locations from the software. No additional maintenance teams are required.

Access Logs and Door Status Reports

Each access attempt is recorded along with the door status. All door or cabinet access information can be exported as a report for internal QC checks.

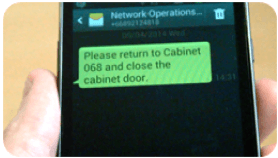

AKCess Pro Server can make a phone call to maintenance engineers if the remote BTS site they have been working on has not be secured correctly after having left the site.

Unanswered calls can be automatically escalated to a follow up SMS or Email notification sent to multiple recipients.

AKCess Pro Server can also trigger additional on-site preventative measures such as turning on a siren alarm, a cooling system or a camera.

Off-grid rechargable power supply and battery monitoring

AKCP remote units can be used off-grid with a solar panel and battery charge controller. When in ultra low power mode, AKCP remote units draw a limited amount of power from the battery. This not only extends the life of the battery due to lowering heat dissipation, but also limits the amount of time taken to recharge the battery. This comes in useful in days of limited sunlight hours.

Temperature and Battery Health monitoring sensors can be added to check battery health so that scheduled maintenance can be arranged before power outages occur.

Synchronize Video with Event Data

Cabinet and Door Access videos can be reviewed using AKCess Pro Server from the central location. Review hundreds of hours of cabinet access attempts and filter to find critical status video in seconds.

Cameras can be embedded into remote site cabinets to capture entry attempts on cabinets or in telecom rooms.

Choose to record 24/7 or on a sensor event to limit overall bandwidth usage.

AKCess Pro Server takes the best from IP Video Monitoring Software and is the first to combine it with Environmental / Security Sensor and Access Control equipment in one centralized management software package.

Monitoring

- Monitor and control all AKCP or SNMP devices from a single display.

- Create drill-down maps of any sensor or camera connected to the system.

- Manage devices from any location.

- Create multiple user accounts to allow or deny access to specific range of devices.

- Monitor 100’s of IP Cameras.

Access Control

- Add and manage users, groups and door or cabinet access schedules – from any location.

- Access Control devices operate even when communication to the Server is interrupted.

- Create custom access log reports and export to CSV for integration with third party software.

- Limit user permissions so that personal data remains safe and secure.

- Deny / Revoke User Permissions at any time.

- Unlock Doors Remotely

Time and Attendance

- Create shifts to manage working hours and holidays.

- Automatically deduct lunch breaks and monitor employee tardiness.

- Create custom time and attendance reports and export to CSV for integration with third party software.

- Link door events to video recording to review disputed clock in / clock out events.

Notifications

- Deploy your own hierarchy of redundant alert notifications using SMS, Email, MMS, phone calls, fax, or use a relay switch to trigger corrective action.

- Escalate notifications that have gone unanswered. For example, follow up on a phone call with a text message or email alert.

- Set up windows notifications to view who has entered or exited your facility at any time.

- Generate emails with picture and video attachments to capture unauthorized entry attempts.

- Link Actions to Icons on the Mapping screen to remotely activate corrective actions.

Video Recording

- Embed cameras into remote site locations to capture entry attempts on cabinets or telecom rooms.

- Record 24/7 or on a sensor event to limited overall bandwidth usage.

- Connect any ONVIF IP compliant camera or one of AKCP’s High Resolution Digital Cameras.

- View up to 50 cameras simultaneously per server installation.

Protect against water and smoke damage

AKCP environmental monitoring allows for intelligent sensor to be connected to AKCP base units such as the securityProbe or sensorProbe series. Sensors are automatically recognized using AKCP’s AutoSense feature. AKCP lets you monitor and control :

- Temperature

- Humidity

- Smoke

- Water leakage

- Air Flow

- Security Sensors

- Motion Detectors

- Detection of AC Power Line Voltage

- Measurement of Digital Voltmeter

- Control Relays and more…

The AKCP base units work standalone or can be used with AKCess Pro Server. All sensors include an integrated data collection and graphing package; especially useful in trend and information analysis.

For example, spotWater Sensors can be used to detect water leaks from CRAC systems. Smoke Detectors can be used to detect the initial signs of component fires in data cabinets.

Events that lead to disaster can be used to proactively alert data center staff to maintain equipment correctly or to take corrective action. When events occur, the AKCP base unit or AKCess Pro Server can be configured to send :

- SNMP Traps

- Email Messages

- SMS

- Telephone Calls

- Audio Alerts

- Relay On/Off Signals and more…

Monitor air flow, temperature and humidity

An essential part of any computer room monitoring system is accurate temperature and humidity monitoring and knowing when CRAC units are on or offline. Rising temperatures lead to system failure, unwanted downtime and costly repairs.

AKCP’s equipment helps to avoid these costly errors with easy to configure, cost effective systems that are ready to run, right out of the box.

Cabinet Environmental Monitoring Package

Features :

- Monitors Temperature, Humidity and Airflow

- Sends SNMPTraps and Email Alerts when thresholds are exceeded

Includes:

- sensorProbe2

- Temperature and Humidity Sensor

- Air Flow Sensor

- AKCess Pro Server SP2 License

Data Room Security Monitoring

Features :

- Detect motion in sensitive IT rooms

- Send SNMP Traps and Email Alerts

- Detect if racks are open or closed

- Prevent disaster with Smoke Detectors

Includes:

- sensorProbe8

- Siren Strobe Alarm

- Motion Detection

- Security Sensors

- Smoke Detectors

- AKCess Pro Server sensorProbe8 License

Graphing of sensor data

Up to 12 AKCP Sensors can be graphed on an AKCP base unit. The AKCess Pro Server allows for an unlimited number of graphs to be monitored.

Customizable Virtual Sensors

AKCP’s Virtual Sensors collect data from third party equipment and can also use the information to send out alerts. Virtual Sensors can be configured to poll data via :

- SNMP Get / SNMP Receiver

- MODBUS

- Custom BASH / PERL Scripting