Sidebar

Data Center Resources Takes the Risk out of Having Your Data Center Cleaned

For Data Centers, Computer Equipment Rooms, Server Rooms, MPOE Rooms, Demarcation Rooms, Central offices, Data Storage Rooms, AMP Sites and Telecommunication Rooms.

One of our highly specialized cleaning technicians will visit your location and inspect your clean rooms, server rooms and other sensitive data storage areas. The initial inspection will give our technician the information needed to offer solutions for the proper maintenance and cleaning. Data Center Resources will identify contamination and other threats that could cost you in reduced productivity, customer satisfaction and lost revenue. DCR uses proven techniques to remove dirt, dust, and other contaminants from your controlled environment. Not only the ones you can see, but more importantly the hidden ones you can’t see.

Features

- Data Center Cleaning

- Sub-Floor Cleaning

- Sub-Floor Sealing

- Equipment And Above-Floor Cleaning

- Above-Ceiling Cleaning

- Anti-Static Floor Cleaning & Restoring

- Anti-Static Floor Stripping & Refinishing

- MEP Room Cleaning

- Zinc And Tin Whisker Remediation

- Disaster Recovery

- Environmental Audits And Reporting

- Inspections

- Air Particle Measurements

Specifications

- Data Center Resources Only Uses Approved Anti-Static And Static Dissipative Cleaners Specifically Created For Your Critical Environment.

- Our Commercial Professional Grade HEPA Vacuums Are 99.97% Efficient At Filtering Particulates Measuring 0.3 Microns And Larger With 1197 Sq. In. HEPA Filtration Area.

- We Use Distilled Filtered Water And Anti-Static Cloths, Wipes And Mops.

- The ISO 14644 Series Of Standards (14644-1 To 14644-8) Are A Series Of Documents That Establish Various Classifications For Cleanliness. This ISO Standard Differs From Another Standard Developed By The U.S. Government Called FS209E. The Yardstick For Measuring Cleanliness Is The Amount (In Size And Number) Of Microscopic Particles Found Per Cubic Meter Of Air. A Small Amount Of Very Small Particles Means And Extremely Clean Environment.

- Most Data Centers Need To Be Kept Clean So They Meet ISO Class 8 Or 9 Standards. Class 8 Allows 3.52 Million 0.5μm Particles Per Cubic Meter, While Class 9 Ramps Up The 0.5μm Particle Size Allowance By A Factor Of 10, Up To 35.2 Million Particles Per Cubic Meter Of Air.

- Certified In Data Center Cleaning

- Highly Vetted And Background Checked

- US Citizens

- Technical Backgrounds

- Understand The Data Center Environment

- Our Disaster Recovery Crews Are Available 24 Hour A Day To Clean Anytime A Disaster Strikes Your Critical Environment.

- Whether It Is Fire, Flood, Fire Suppressant Discharge Or Any Emergency That Disrupts Your Normal Operations.

The Efficiency Report Card is a service to assess the effectiveness of the current data center cooling infrastructure. Measurements of temperature, airflow and power utilization in key areas provide data to compare to industry benchmarks and best practices. Based on the data collected, specific actions are suggested for improvement.

Our Cooling Specialist will take readings at your CRAC/CRAH units, cold aisles, hot aisles and other locations in the data center. The collected data will be used to create metrics, such as Delta T’s and Efficiency Ratios. These metrics are then compared to industry bench marks to provide a relative snapshot of the current cooling efficiency.

Specific action items will be created based any problem areas identified. All suggested actions are based on best-practices proven to counteract the specific issues discovered. The purpose of the Efficiency Report Card is to maximize the performance and efficiency of the cooling infrastructure so adding additional capacity will not be a corrective action.

Features

- Achieve Higher Delta T Of Supply And Return Air For Higher Capacity And Efficiency

- Minimize Bypass Airflow Which Is Wasted Cooling Capacity

- Identify Airflow Issues Which Result In Hot Spots

- Determine The ‘Actual’ Cooling Capacity Of Cooling Units

- Identify Best Cooling Best Practices Which Can Improve Efficiency

Specifications

- Increase Cooling Capacity, Even Above What Is Stated On Cooling Units

- Improve Reliability Of Servers By Ensuring Optimal Operating Environment

- Avoid Costly Investments On New Cooling Units By Maximizing Existing Infrastructure

- Improve Efficiency Without Downtime Or Disruption

- Save 15 To 50% On Energy Costs For Cooling

The battery is the most vulnerable part of any backup power system, regardless of capacity, topology or brand. Understanding causes of UPS battery degradation, ways to prevent degradation and UPS battery maintenance options are fundamental to ensure maximum system availability and to keeping your data center and business up and running. We have experience in managing battery systems for some of the largest data center operators in the world. Our field team is highly experienced and trained to perform battery projects in an efficient and safe manner. Whether you need a full battery installation or a spot replacement, we provide complete end-to-end project management coordination to ensure a successful implementation.

Correct battery sizing for optimum run-time and maintainability saves money and space while avoiding outages. We can help properly size your battery systems taking into consideration both beginning of life and end of life requirements. This is where the rubber meets the road and why our expertise and experience really matters. Backup Batteries for UPS, Generator, Switchgear, and DC Plant. Warranty matters, and since we maintain the entire data history for your systems, we are able to certify each battery’s history against the manufacturer’s specifications–ideal when it comes to getting units replaced.

Features

- Battery Projects Include Staging, Transportation, Shipping, Installation And Disposal. When Necessary Our Staff Will Perform A Preliminary Walk-Through Of Your Facility To Identify Logistical Challenges Ahead Of Time. On-Site Certified Field Technicians Will Perform New Install Or Battery Replacement And System Configuration. We Will Also Dispose Of Your Old Batteries To An Environmental Regulatory Compliant Battery Recycling Center.

- Quarterly, Semi-Annual Or Annual On Site Inspections Include; Validation Of Ohmic, Voltage And Temperature Measures, Calibration, Wire Harness Connection Checks And Annual Battery System Visual Inspections.

- Facilitation Of Battery Return Merchandise Authorization (RMA) Process And Replacement Including Warranty Management. If Monitored, Canara Has The Ability To Include Battery Performance History To Expedite Warranty Claims.

- IEEE 1188 Compliant Load Test Can Be Performed At Installation Or Annually To Simulate Client Load And Prove Overall System Integrity And Prove All Units Pass In Accordance With The Manufacturer’s Specifications. Canara Will Perform A Complete Analysis Of The Resulting Data And Provide A Detailed Report As To Which Batteries Pass/ Fail The Load Testing. This Ensures That Weak Batteries Are Removed From The String Immediately For Better Warranty Claim And Longer Life String Performance.

- Predictive Analytics And Monitoring Of Your Batteries Provide The Visibility Into Your Battery System So Spot Replacements Can Be Planned In Advanced And Timed With Pre-Scheduled PM Or Service Visits.

- Trained Technicians Use Non-Intrusive, Thermal Imaging Technology To Detect Defects Before They Can Cause A Major Issue.

Specifications

- Save Time, Money And Ensure Your Systems Are Operational

- Full Turnkey Management Service For All Your Battery Assets

DCR has a nationwide installation network unmatched in experience and capabilities.

Data Center Resources offers aisle containment, control room console furniture, and server cabinet installation services. We have over 15 years of professional experience installing in critical facilities. Our installers have the expertise to complete critical projects in a professional and timely manner.

Data Center Resources Provides

- Experienced aisle containment installers

- Experienced console installers

- Experienced server cabinet installers

- Full-service installation for small, medium and enterprise projects

- Installation of greenfield and retrofit sites

- Professional leadership for efficient team approach

- Optional off-hour installation services

- Installers with forklift and scissor lift certifications

Our excellent reviews confirm our commitment of offering a high quality service.

The ability to provide a complete solution from design to installation makes us different. Most other containment solutions are not manufactured by the same company that manages delivery and installation. On a large project, this can lead to communication issues, finger-pointing and difficulty adapting to changes. Well over 100 end-to-end aisle containment installations have seasoned our project managers in planning and implementing quality total solutions on time and on budget smoothly.

Construction Project Management

- Experience with Davis-Bacon prevailing wage reporting

- Ability to provide detailed drawings including CAD and BIM files

- Experience with AIA billing and project reporting

- Experienced leadership in design, implementation through commissioning

- Collaboration with architects, engineers and other trades

- Concise project scheduling and reporting

- Professional drawing and design documentation

- Exceptional logistics and material management

Overview

Monitor Your Generator & Fuel Online

Ensuring your Generator is healthy and ready when needed is of paramount importance to avoid interruption to daily operations. But how do you know your generator is being maintained, that there is fuel in the tank or how many hours it has run? Using AKCP’s Generator Monitoring Solution you can now achieve all of this and more.

sensorProbe+

The sensorProbe+ platform (SP2+, SPX+) is the heart of this solution. For low cost, simple installations, the SP2+ can be deployed. A robust and compact device, it can connect with up to 3 sensors and has an RS485 port for connecting with Modbus or Canbus outputs from the genset control panel. SPX+ is ideal where more than simple generator and fuel monitoring is required. Available in custom configurations with additional sensor ports, dry contact inputs and input/output (I/O) modules it provides a complete monitoring solution for remote sites. All sensorProbe+ devices are available with an optional cellular data modem to ensure communications even at sites without a cable connection.

Ultrasonic Fuel Level Sensor

The UFLS is installed on standby fuel tanks. Suitable for tanks up to a maximum depth of 2 meters it will constantly monitor the level in your tank and provide you with accurate readings. Know your generator is fueled and ready to go, as well as monitoring for potential fuel theft.

Real Time Monitoring

Every sensorProbe+ has it’s own web server and user interface, which provides real-time monitoring of the generator and attached sensors. An engine gauge dashboard presents the parameters in a graphical, easy to read format. Graphing of data points, and configuration of thresholds for alerts can all be managed through this user interface.

For installations at multiple sites over a wide geographic area, AKCP Pro Server will manage all your devices from a single user interface. Ideal for centralized monitoring of your infrastructure. Drill down mapping gives an overview of your sites, their locations and ability to zoom in to specific sites. Integration with ONVIF IP cameras gives “eyes on” at each site, with video being synchronized with sensor events. AKCP’s access control solution can be deployed to manage access at each site, and is also administered through this central management software.

Maintenance Alerts

Keep your generators scheduled and preventative maintenance up to date. Be alerted when a generator reaches a specified number of run-time hours. Never miss an oil change, or put your generator at risk of not being ready just when you need it the most.

Generator Monitoring

Remote Generator Monitoring

Monitoring over RS485 Modbus / Canbus

For generators with an RS485 connection from the control panel, the sensorProbe+ can monitor a wide range of parameters such as engine speed, oil pressure, runtime hours, KVA output, temperatures. Any engine data that is available from your control panel can be monitored from a dedicated graphical dashboard on the sensorProbe+ web interface or, for multiple sites, centrally at AKCP Pro Server.

Monitoring with hardware sensors

Not all generators are equipped with an RS485 output. In this case, hardware sensors can be connected to the sensorProbe+.

Ultrasonic Fuel Level Sensor (UFLS)

The UFLS is mounted on your standby fuel tanks so you can check on the fuel status, know when to refuel and detect potential fuel theft.

DC Voltmeter (iDCV)

Monitor the generator starter battery with the DC Voltmeter to ensure that the battery is in good condition and providing sufficient voltage.

Temperature Sensor (TMP00)

Temperature sensors can be deployed in the generator enclosure to alert should the temeprature reach a critical level.

AC Voltage Sensor (ACV00)

Use the AC Voltage sensor to check generator on/off status. It can be used as a feedback to verify AC Voltage is present when the generator is turned on.

Power Meter (PMS)

Power meters, and current transformers can be deployed to monitor power output from the generator and verify engine runtime hours.

Fuel Monitoring

Remote Fuel Monitoring

Ultrasonic Fuel Level Sensors

Invasive and non-invasive ultrasonic fuel level sensors are available to monitor your standby fuel tanks. Suitable for tanks up to a maximum depth of 2 meters, you can keep track of fuel level, usage, and detect potential fuel theft. The sensor connects to an available sensor port on the sensorProbe+ device, and the tank profile can be programmed through the user interface so readings are accurate.

Monitoring AC line voltage in IT environments.

Sensor Overview

AC Voltage Sensors from REGY are designed to be used anywhere in the world. When the presence or absence of voltage has been detected the AC Voltage Sensor indicates an Alarm / Normal condition.

SNMP traps can be configured to send when critical conditions occur. SNMP polling via ‘get’ commands is available to retrieve existing status and configuration parameters.

Ease of Installation

All sensors ship with the cables and accessories required for a basic installation and use RJ45 ports for plug and play connectivity. REGY use industry standard CAT5e cables for all sensor extension cabling. For more advanced installations, sensor cables can be cut to length on site or you can ask our sales team for custom length sensor extension cables prior to ordering.

Platform Support

Both the sensorProbe and securityProbe platforms support AC Voltage Detection Sensors

Unexpected system downtime is incredibly costly to a data center.

A study from Ponemon Institute in 2013 showed that the average cost of data center downtime is approximately $7,900 USD per minute and rising. Average incident lengths are approximately 86 minutes, resulting in an average cost per incident of approximately $679,400 USD.

REGY provides sensor monitoring platforms assisting in the prevention of system downtime by proactively alerting staff to maintain equipment and taking automated, corrective actions.

AC Line Voltage Alerts & Notifications

Create alerts and notifications to automate corrective action. Automatically start backup power systems such as generators. http://www.regy.com.sg/solutions/ac-line-voltage-detection/Gracefully shut down non-essential servers using sophisticated software scripting and sending email or SNMP traps to maintenance teams.

Once the main AC service line has been restored, use notifications to safely turn off backup power systems, wake up servers in standby mode as well as automatically documenting the downtime recording battery and generator runtimes for maintenance purposes.

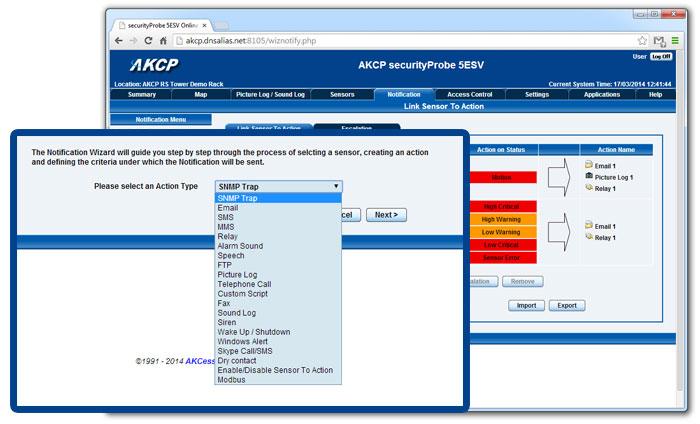

A wide variety of notification actions can be created to automate corrective action on specific sensor events.

Single & Multi-point Water Leak Detection for CRAC Units.

Monitor CRAC Water Leaks.

Monitor air conditioner water leaks in server rooms. Water leaks can lead to system failures and unwanted downtime. Use sensor notifications to detect water leaks in small, medium or large areas.

Combine with temperature, air flow and dry contact status monitoring to collect real time computer room air conditioner CRAC status.

Sensor Alerts and Notifications can be sent when water has been detected. If for some reason a cable becomes dislodged or damaged, an error status will alert server room maintained personnel to the fault.

AKCP manufacture a range of water leak detection sensors for use in computer rooms, server rooms and large scale data centers. AKCP sensors can be placed on a number of surfaces and mounted in raised floor air conditioning ducts. For self-contained rack air conditioning units, rope detection sensors are an invaluable asset in protecting against localized water leaks.

Tabbed screw holes for simple mounting on any surface. Dual sequence LED for sensor warnings. RJ45 Plug and Play connectivity.

There are three types of water detection sensor provided by AKCP.

- spotWater Sensors – single point detection

- ropeWater Sensors – single point detection

- locateWater Sensors – multiple detection points

Water Detection Alerts & Notifications

AKCP provide a wide range of notifications, not limited to email, snmptraps, automated telephone calls and sms messages (when using AKCP’s optional USB or Internal 3G Modems). Additional automation can be performed such as shutting down one CRAC unit and stabilizing server room temperatures with another CRAC system until maintenance personnel can resolve the water leak. Add siren strobe alarms to draw immediate attention to water detected within mission critical areas of a data center.

spotWater Sensor

The spotWater Sensor is an advanced microprocessor based designed capable of detecting distilled water. Standard water detectors are unable to detect distilled water and water with impurities due to them using a resistance type circuit. The spotWater sensor is encased in epoxy giving it a waterproof finish. It is able to withstand being submerged in water for prolonged periods. SNMP OID’s are included for monitoring across a network.

ropeWater Sensor

The ropeWater Sensor protects essential equipment from potentially harmful water damage. It forms an integral part of your disaster prevention system. Ideal for use in basements, under false floors and ceiling spaces, the ropeWater Sensor covers a large area and give a single point sensor alarm of water leaks or flooding. http://www.akcp.com/solutions/crac-water-leak-detection-monitoring/SNMP OID’s are included for monitoring via an network management software.

locateWater Sensor

The locateWater Sensor gives a precise location of a water leak so that maintenance personnel can respond promptly to protect server room assets from water damage. It is ideal for use in hard to reach areas of a data center, such as raised floor and false ceilings. This sensor comes fully assembled and includes the rope portion that is the water sensing cable, the non-sensing cable (from the rope to the sensing module) and the main sensing module.

Intelligent temperature monitoring for server cabinets.

AKCP temperature sensors are easy to install and include extensive support documentation.

Temperature sensors ship with the cables and accessories required for basic temperature sensor installations.

Monitor temperature. Lower CRAC setpoints. Reduce costs.

Start with a single sensorProbe and a dual temperature & humidity sensor to monitor server cabinet temperature & humidity. Add more temperature sensors and locate hot spots within a server cabinet.

Assign temperature sensors and internal server CPU temperatures to AKCP’s ThermalMap software to visualize in real time server rack temperature. Use collected temperature sensor data to safely raise air conditioner temperature setpoints without putting mission critical equipment at risk.

Save on server room cooling costs and lower server room PUE one rack at a time.

Temperature Sensor Graphing

AKCP sensorProbe and securityProbe units include a HTML user interface providing a overview of all connected sensors.

The graph for each sensor can be customized to show a specific time range using an easy to use option menu.

RRD tool is used to build an embedded database of sensor data. All sensor data can be accessed from the web interface,or downloaded to a remote PC.

Sensor graphs can be enabled for up to 16 sensors on the securityProbe.*

SENSOR GRAPHING IS INCLUDED WITH ALL SENSORPROBE AND SECURITYPROBE BASE UNITS.

MONITOR UP TO 16 GRAPHS ON THE SECURITYPROBE.

Easy to install. Mass configuration tools included.

AKCP temperature sensors are easy to install and include extensive support documentation. Temperature sensors ship with the cables and accessories required for basic temperature sensor installations.

All AKCP sensors use a standard RJ45 network connector and CAT5 cabling. Custom sensor cable lengths can be specified when ordering or, for advanced installations, can be extended to the required length on-site.

Use the embedded sensor configuration web interface or AKCP’s DCIM Software, AKCess Pro Server to configure the temperature sensor. Set a range of sensor thresholds to use with sensor notification wizards. Features such as “Continuous Time” avoid multiple notifications when temperature fluctuates rapidly between threshold set-points. Deploy to 1000’s of cabinets with a single configuration file.

AKCP temperature sensors are easy to install and include extensive support documentation.

Temperature sensors ship with the cables and accessories required for basic temperature sensor installations.

Example Configurations

Temperature Sensor Alerts & Notifications

An essential part of any server room monitoring system is accurate temperature and humidity monitoring. High temperatures can lead to system failure, unwanted downtime and costly repairs.

AKCP platforms help to avoid these costly errors with easy to configure, cost effective systems that are ready to run, right out of the box.

Events that lead to disaster can be used to proactively alert IT staff to maintain equipment correctly or to take corrective action.

SNMP Enabled Temperature Sensors

AKCP actively maintains a downloadable sensor MIB file containing SNMP OID references to AKCP sensors and equipment.

In addition, all sensor OIDs can be accessed directly from the web user interface. Sensor integration guides are available for most popular NMS softwares such as Nagios, Solarwinds, PRTG Network Monitor, HP OpenView and more…

AKCP sensorProbes are SNMPV1 & V2 compliant. AKCP securityProbes are SNMPv3 compliant with full encryption.

A plenum fan tray to improve airflow to cabinets where underfloor static pressure is insufficient.

More...

High Efficiency Rack Cooler. Delivers cooling air where and when it is needed

66% perforated high flow floor tile to help cool high density racks & hot spots.

55% perforated high flow floor tile to help cool high density racks & hot spots.

Air-Flow Panel provides both strength and performance in an attractive package.